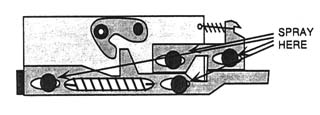

Figure 21 Spray away the old grease with WD-40.

12. WD-40 both removes the old grease and relubricates the drive. No additional lubrication is necessary. Reverse steps 8 through 1 to reassemble the repaired disk drive.

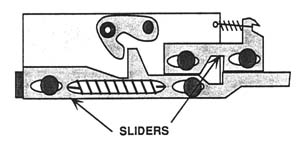

Relubricated carrier mechanisms work as good as new. Repairs last indefinitely because, unlike grease, WD-40 can't solidify.

Figure 22 Work the sliders back and forth until all of the old grease is gone.

The same procedure works for 400K Macintosh disk drives as well. The lubrication principles also apply to 800K Mac drives. Unless you operate in an hermetically sealed environment, all autoeject drives eventually develop problems with the carrier mechanism. Tiny eject motors don't have nearly the same strength as a human finger on a push button, Periodic relubrication is (or at least it should be) part of routine maintenance.

Drive Does Not Make Eject Noises and Disks Get Stuck

Occasional eject failures which are not accompanied by eject noises indicate that the OEM Lisa drive has been replaced with an OEM Mac drive. Despite the mechanical similarity between 400K drives (right down to the part numbers!), the OEM Lisa model has a different eject mechanism. It's always triggered on shutdown, whether there's a disk in the drive or not. The OEM Mac model is not triggered, unless there is a disk in the drive. Since the Lisa can't do a disk check after a System crash, Mac drives fail to eject them when you restart the computer. Inserted disks remain in the drive, and the Lisa's boot ROM doesn't know what to make of them. There are three possible fixes.

One is to drill a 1/16 inch hole to the right of the drive opening (just like small Macs) and use a straightened heavy-duty paper clip to eject the disks. The second is to repair and reinstall the original Lisa drive. The third is to install MacWorks Plus version 1.0. 18 or later. Because MacWorks Plus includes 800K drive support, and since the only difference between a 800K Lisa drive and an BOOK Mac drive is the mounting hardware, this problem was (and had to be) taken care of, or the 800K Lisa disk drive would malfunction exactly the same way. MacWorks Plus cures many long-standing Lisa problems. We'll be taking a very close look at it towards the end of this publication.

Grinding Noises

Grinding from the disk drive indicates a dirty stepper cam, a dirty head, and / or a clogged pressure pad. Clean the cam shaft with cotton swabs and WD-40, but don't loosen the cam retaining screw. Dirty heads should be cleaned the same as tape recorder